Features:

- Split Plant Cooling Unit

- Wall Plant Cooling Unit

- Roof Plant Cooling Unit

- Chill, freezer or variable temperature available

In order to create your cooling system, we have two options, and we can discuss with you which we think would work best for your needs.

We utilise Monoblocks which are a single unit that can be mounted on the wall or ceiling of the cold store cabinet/room. These units are sealed and self-contained meaning that they are ideal for use in confined but well-ventilated spaces.

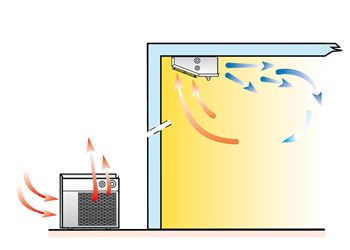

We also use Split Plants where two cooling units are needed. One of these units is located inside the cold room or body store and one is located outside. Split Plants are ideal for enclosed, cramped, and tight spaces with the exterior condensation unit housed outside, which means that the evaporator does not take up a lot of space.

Both Monoblocks and Split Plants can be set up as chill, freezer or variable temperature (chill/freezer) units, dependant on the required specification so please do not hesitate to get in touch to discuss your requirements.

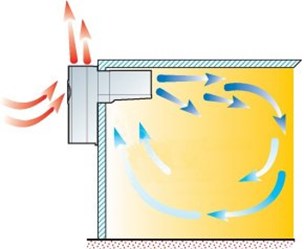

Wall-mounted Cooling Unit

|

|

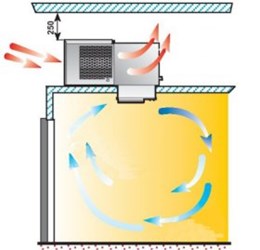

Roof-top Mounted Cooling Unit

|

|

Split Cooling Unit

|

|